In the realm of high-end smartphones, the iPhone 15 Pro Max stands out not just for its impressive features but for the distinction of being the costliest phone ever produced.

Costlier than Ever

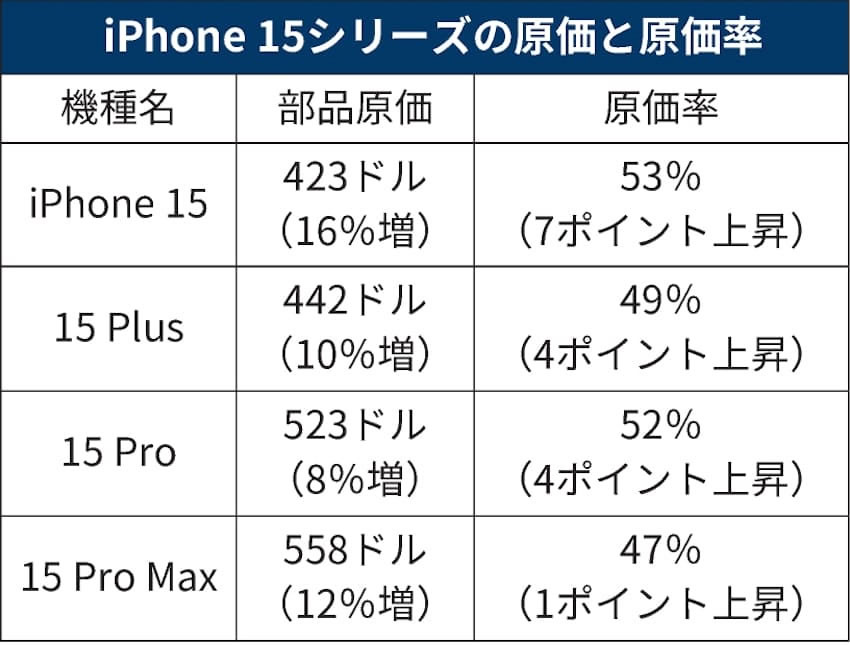

When compared to its predecessor, this smartphone comes at a 12% higher manufacturing expense. Calculations indicate that the cost of production for the iPhone 15 Pro Max amounts to a remarkable $558. It’s a notable increase when we consider the entire iPhone 15 series in contrast to its forerunner.

The increase in manufacturing costs can be attributed to several factors. Notably, the inclusion of the 5x zoom-capable tetraprism telephoto camera is a significant contributor. Improvements in other components across the board have also raised the production costs. This trend collectively pushes the iPhone 15 Pro Max into the spotlight as the most expensive flagship smartphone to date, with a production cost of $558.

Pricing Strategy

Apple, recognized for its innovations and quality, decided to release the iPhone 15 Pro Max at a price point of $1,199, marking a significant $100 rise from the preceding model. The pricing strategy is rooted in several underlying factors that are altering the landscape of high-end smartphones.

The enhanced camera capabilities, including the advanced 5x zoom tetraprism telephoto lens, are among the critical features that have contributed to the iPhone 15 Pro Max’s price increase. Alongside these camera improvements, other components across the entire iPhone 15 series have received upgrades. This collective enhancement is reflected in the elevated production cost of the iPhone 15 Pro Max, making it the most expensive flagship smartphone to date.

The Increasing Manufacturing Costs of the iPhone 15 Series

A report by Nikkei provides some in-depth insights into the iPhone 15 series, revealing that it costs 8-16% more to manufacture these models compared to the iPhone 14 series. The cost breakdown is even more remarkable when we focus on the top-tier model, the iPhone 15 Pro Max.

The Pinnacle: iPhone 15 Pro Max

The iPhone 15 Pro Max surpasses its predecessor, the iPhone 14 Pro Max, with a 12% increase in production costs. This model’s component cost ratio stands at a significant 47%.

The increased manufacturing expenses of the iPhone 15 series as a whole become particularly noticeable when we turn our attention to the flagship model, the iPhone 15 Pro Max. It marks a significant 12% increase in production costs when compared to its predecessor, the iPhone 14 Pro Max. The component cost ratio for this model stands at a substantial 47%.

Across the Series

The costlier trend isn’t exclusive to the iPhone 15 Pro Max. The report indicates that the entire iPhone 15 series exhibits higher production costs compared to the iPhone 14 series.

The trend of elevated manufacturing expenses extends across the entire iPhone 15 series. For instance, the iPhone 15 Pro, with a production cost of $523, exhibits an 8% increase in manufacturing expenses when compared to the iPhone 14 Pro. Meanwhile, the iPhone 15 Plus, priced at $442, sees a 10% increase in production costs when compared to its predecessor.

The Value Proposition

The price hike accompanying the iPhone 15 series becomes all the more intriguing when we consider that the model hasn’t introduced a significant number of groundbreaking innovations.

The iPhone 15 series hasn’t introduced a significant number of groundbreaking innovations for its higher cost. Therefore It raises the question of how these elevated costs translate into enhanced user experiences and whether consumers view the added expense as justifiable.

The High Cost of Innovation

Diving deeper into the report, we find fascinating details such as the revelation that the new tetraprism 5x telephoto lens costs a whopping 380% more than the previous 3x optical zoom lens.

Expensive Components

The report highlights that the costliest components within these devices are undoubtedly the A17 Pro chip and LTPO OLED panels. These vital elements contribute significantly to the overall manufacturing expenses, underlining the focus on innovation and quality within Apple’s flagship models.

Also, the report delves into the cost breakdown of the iPhone 15 series, identifying certain components as primary cost drivers. Among them, the A17 Pro chip and LTPO OLED panels stand out as the costliest elements. This insight showcases Apple’s unwavering commitment to incorporating innovative and high-quality components in its flagship models, even at an elevated production cost.

Future Efficiency

Furthermore, Apple has plans to use the A18 chips in iPhones set to launch next year. Hence these chips are expected to be more cost-efficient due to their production through the higher-yielding N3E manufacturing process by TSMC, offering the potential for a slight reduction in manufacturing costs.

The future efficiency of Apple’s manufacturing process becomes a point of interest. The Nikkei’s report anticipates the use of A18 chips in the iPhones set to launch in the upcoming year. These chips are expected to be more cost-efficient, primarily due to their production through the higher-yielding N3E manufacturing process by TSMC. The adoption of these chips is likely to bring about a marginal reduction in manufacturing expenses. As a result, it offers a potential respite from the elevated costs associated with high-end smartphone production.

In Conclusion

In conclusion, it’s evident that smartphones like the iPhone 15 Pro Max may come at a premium. Because they represent a combination of cutting-edge technology and an investment in quality that places them in a league of their own. Moreover, the cost is not just a reflection of the device’s current capabilities but a bet on its future-proof design and long-term value. The escalating manufacturing expenses underscore the pursuit of innovation and excellence. Finally, these high-end devices continue to push the boundaries of what’s possible in the world of smartphones.